GREEN FOAM XPS - THERMAL INSULATION BOARDS

GREEN FOAM XPS - THERMAL INSULATION BOARDS

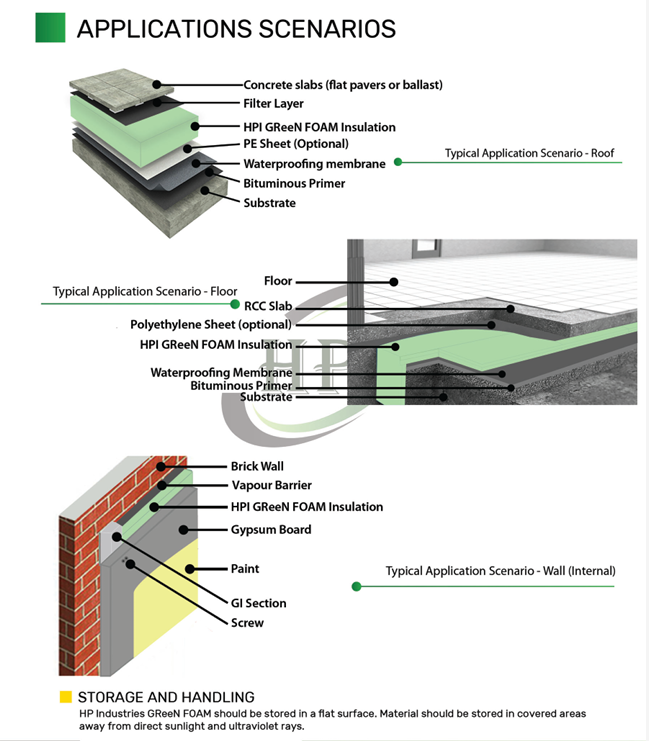

HP Industries green foam extruded polystyrene panels are specially formulated to suit the very harsh middle eastern climatic conditions. HP industry’s green foam is an intelligent way to insulate a building. It has the lowest global warming and acid rain potential and the highest energy saving for thermal insulation work. HPI green foam is available in several different densities and has an R-value at 75°F ( 24°C ) of about 5 per inch. HPI Green foam has a very high capacity, enabling it to withstand extreme heat up to 80°C ( 176°F ). Especially suitable for middle eastern hot climatic conditions. Its specialty formulation makes the product a uniform combination of high performance and extremely fire-retardant properties, i.e., it is 100 % non-flammable.

| SL.NO | PRODUCT | DESCRIPTION | BRAND DIMENSION ( MM ) |

| 1 | Green FOAM ND(R&W) | Extruded Polystyrene rigid foam with skin , available with and without shiplap edges. |

Width: 600,Length: 1250 Thickness: 50,75, 80 25, 30, 40 available in straight edge only. |

| 2 | Green FOAM MD(R&F) 38 -42 kg/m3 | Extruded Polystyrene rigid foam with dense skin, available with and without shiplap edges. |

Width: 600 ,Length : 1250 Thickness : 50, 75, 80 25, 30, 40 available in straight edge only. |

| 3 | Green FOAM HD(F) 40-45 kg/m3 | Extruded Polystyrene rigid foam with very hard skin skin, available with and without shiplap edges. |

Width: 600 , Length: 1250 Thickness : 50, 75, 80 25, 30, 40 available in straight edge only. |

TECHNICAL DATA

| SL.NO | CHJARACTERISTICS TYPICALLY VALUES | TEST METHOD | UNIT | GREEN FOAM ND ( R& W) | GREEN FOAM MD ( R & F ) | GREEN FOAM HD ( F) |

| 1 | Density Range | ASTMD1622 DIN 53420 |

kg/m³ lb/ft³ |

32 - 35 2.0-2.2 | 38 - 42 2.4-2.6 | 40 - 45 2.5-2.8 |

| 2 | Thermal Conductivity (k) | ASTM C518 | W/mºk | 0.029 | 0.028 | 0.027 |

| 3 | Compressive Strength at 10% deflection | ASTM D 1621 | Kpa psi | 270-340 39-49 | 320-410 46-58 | 410-630 58-92 |

| 4 | Water Vapor Diffusion resistance factor | DIN 52615 | µ | 100-200 | 150-220 | 160-230 |

| 5 | Water Vapor Permeability | ASTM E96 | g/hm2 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| 6 | Water Absorption by Submersion (+1% by Vol. Precision) | BSEN 12087 ASTM D2842 (+1% by Vol. Precision) | %by Vol. %by Vol. | <0.3 <0.1 | <0.3 <0.1 | <0.3 <0.1 |

| BS EN 1609:1997 | Kg/m2 | <0.1 | <0.1 | <0.1 | ||

| 7 | Linear Co-efficient of Thermal Expansion | DIN 52328 | ·c .F |

70x10"6 39x10"6 | 70x10"6 39x10"6 | 70x10"6 39x10"6 |

| 8 | Fire Resting Fire Classification | ISO 11925-2 DIN/ 4102 | None Building Material Class | None B2 too diffucilt to ignite | None B2 too diffucilt to ignite | None B2 too diffucilt to ignite |